Here are some of the designs I came up with. Any suggestions/ideas??

- Elliot -

LED Specs from the manufacturer:

CREE High Power - Tao source of an electronic agent. CREE High Power Products:

1.cree high power led Q5 is white, the color temperature :5700-7000K (WC, WD, WF, WG) Model: XREWHT-L1-Q5 cree led warm white temperature :2600-3700K, warm white natural :3700-5000K, other colors, red, green, blue, yellow. Model: XRE, XRC, XPE, XPC, MCE series.

2. Luminous flux of up to 114LM / W.

3. The normal working current: 350mA-700mA, 700mA at work when the flux is 1.65 times the work of 350mA maximum support, 1000mA

4. Typical voltage 3.2V (350Ma), 3.5V (700mA)

5. CLASS II,> 2000V

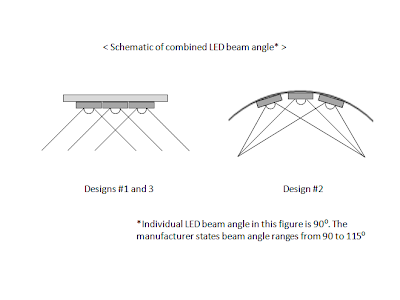

6. Typical viewing angle 90 °, 110 °, 115 °

7.1000 is less than small-time decline 0.5% (350mA, Ta = 25 degrees,)

8.50000 small-time decline of less than 30% (350mA, Ta = 25 degrees,)

9. Meet the ROHS requirements.

10. Thermal resistance within the lowest in the industry: 8 ℃ / W

11. The world's leading JEDEC standards for pre-test

12. Can be reflow line-JEDEC, J-STD-020C standard,

13. Cooling section is not electrically charged.

14. To provide tailor-made aluminum plate (special specifications) tailor-made, (ie, zone plate) LED reflow processing and other supporting services.

15. Application: LED lamps, automotive lighting, stage lighting, mobile phone backlight, architectural lighting, solar lighting, military flashlight; to provide tailor-made aluminum plate (special specifications) tailor-made, (ie, zone plate) LED reflow processing and other support services .